Why Cardboard Procart Spray Booth Filters Are More Efficient Than Glass Fibre

The principle of air filtration in dry spray booths is very simple. The air enters the booth and is drawn, via an extraction fan which also carries any overspray, through an extraction filter. The choice of filter can depend upon the type of paint, lacquer or powder being used as well as the dimensions of the spray booth filter unit and the position of the booth within your factory. Our Procart range includes several different designs to best suit the material to be filtered. If your spray booth is was not originally fitted to receive Procart filters, then most booths can be easily adapted which will ensure your booth has a higher paint holding efficiency as well as being easier to use and better for the environment.

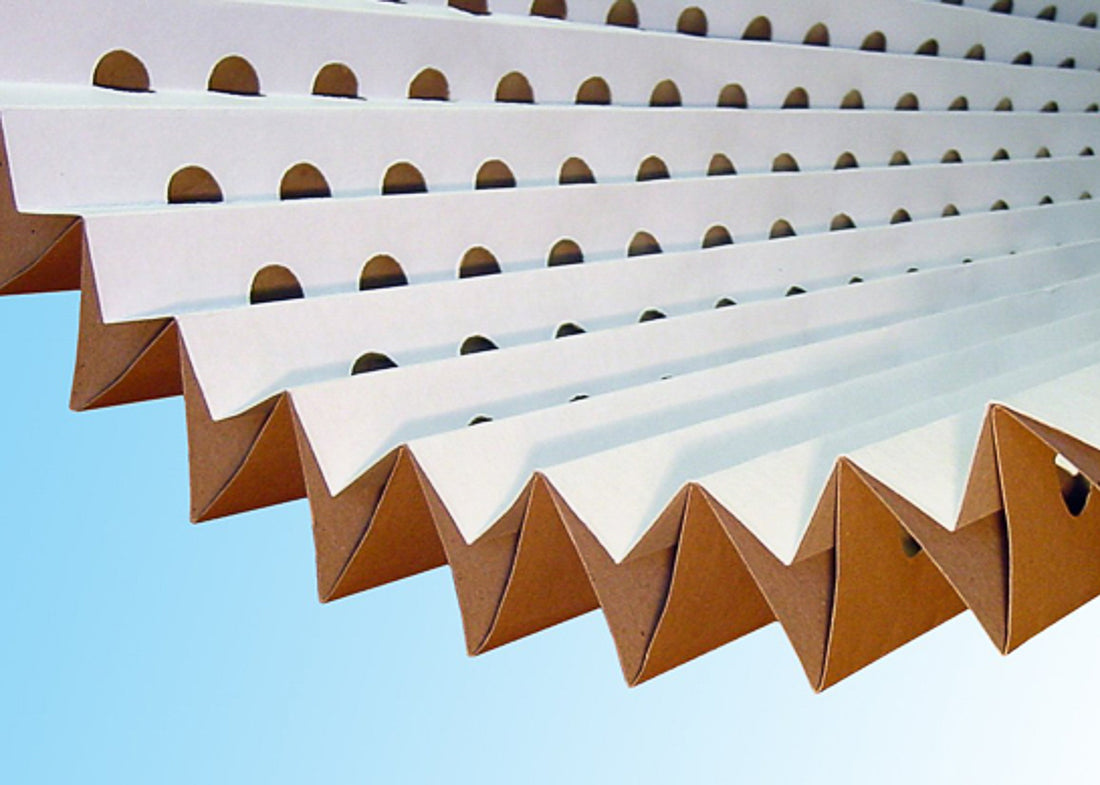

The Procart filter has been designed to capture a high level of paint (or lacquer, varnish, dust etc) whilst maintaining air flow due to the principle of inertial separation. Its 'V' shape, and the offset filter holes, ensure that the paint is held between the layers of filter whilst the air can continue to flow. Therefore, the spray booth airflow can continue, with little or no reduction, until the filter is full at which point it should be changed. When installing a filter from our Procart range, the hole on the 'flat' side faces forward and the accordion 'V' is behind (with filters that have a layer of fibre, this should be facing away from the sprayer, so on the back of the filter. This is the same for our Procart K filters). As the air continues through the filter, the paint cannot change direction and so remains within the filter. The centrifugal effect, of the circulating air, forces the paint particles into contact with the absorbent cardboard where it is held. Typically, a Procart filter will hold more paint (4 to 6 times) and maintain a higher airflow than a fibreglass filter which will become blocked on the surface once it captures any paint.

Our Procart filters come in a range of different designs and efficiencies to ensure that they can be used with any type of paint or coating including very light dust or powder and within all types of booth, even those with a high rate of airflow. Our Procart range prevents the need for a separate secondary filter which will help reduce costs as well as maintenance and installation time.

The concertina design of our Procart filter allows for them to be compressed in a box for easy transport. This packaging takes up less space and so are easier to store than rolls of media and glass fibre rolls. A pallet will hold between 50 - 60 filter boxes in comparison with half that in fibre rolls and media. Our filters come in a range of different sizes, but they can also be easily cut to a different height whilst inside the box, rather than expanding a whole roll of media.

Handling of cardboard filters is easier and safer for personnel as Procart filters are made with 100% natural, recycled paper and water-based glues, all being biodegradable. Media, such as fibreglass, can be an irritant to both skin and breathing.